If you follow the world of electric vehicles (EVs), you’re familiar with the headlines: longer ranges, faster charging, and groundbreaking new models. But behind these flashy advancements lies a less glamorous, yet absolutely critical, piece of engineering: the rigorous testing of the EV's core components.

At the heart of every EV are two key players: the high-voltage battery and the inverter. Ensuring they are robust, efficient, and safe is what makes the modern EV revolution possible. And the unsung hero enabling this rigorous validation? The bidirectional DC power supply.

Let's pop the hood and see why this piece of test equipment is so fundamental.

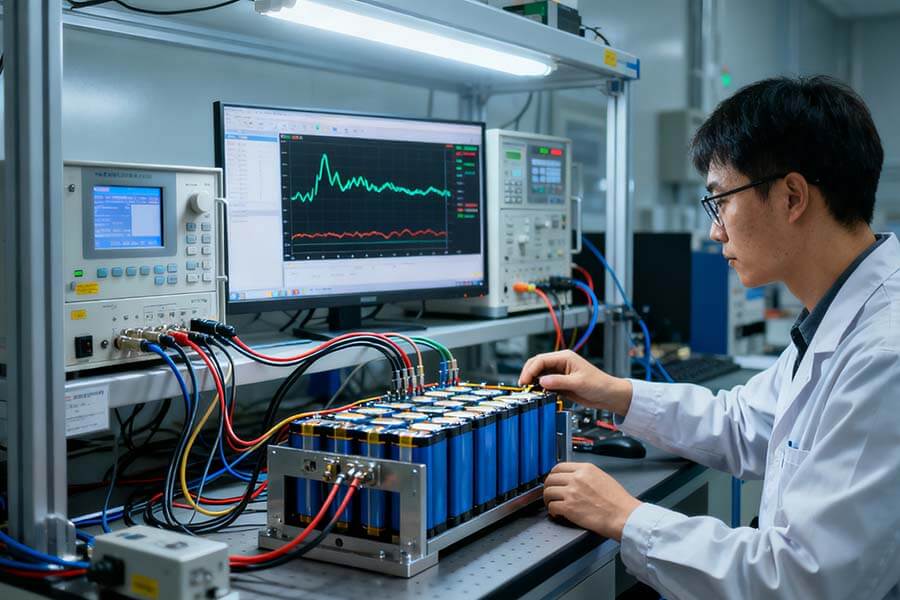

The Beating Heart: The EV Battery Pack

An EV battery isn't just a power source; it's the vehicle's energy reservoir. It must reliably discharge energy to propel the car and gracefully accept energy during regenerative braking and charging. Testing its lifecycle, performance, and safety under all possible scenarios is a monumental task.

A traditional, unidirectional power supply and electronic load can simulate some of these conditions, but it's a clunky, two-piece solution. This is where the bidirectional DC power supply shines.

How it tests the battery:

· Emulating Real-World Driving: It can seamlessly act as a sink for energy (source mode) to simulate the battery powering the motor, and then instantly switch to providing energy (load mode) to simulate regenerative braking or grid charging. This allows engineers to test battery management systems (BMS) and cycle the battery thousands of times to predict its lifespan.

· V2G (Vehicle-to-Grid) Testing: The future of EVs is bidirectional. Your car could one day power your home during an outage or sell energy back to the grid. A bidirectional supply is essential for testing this function, accurately mimicking the grid's conditions to ensure the inverter and battery can handle the complex power flow.

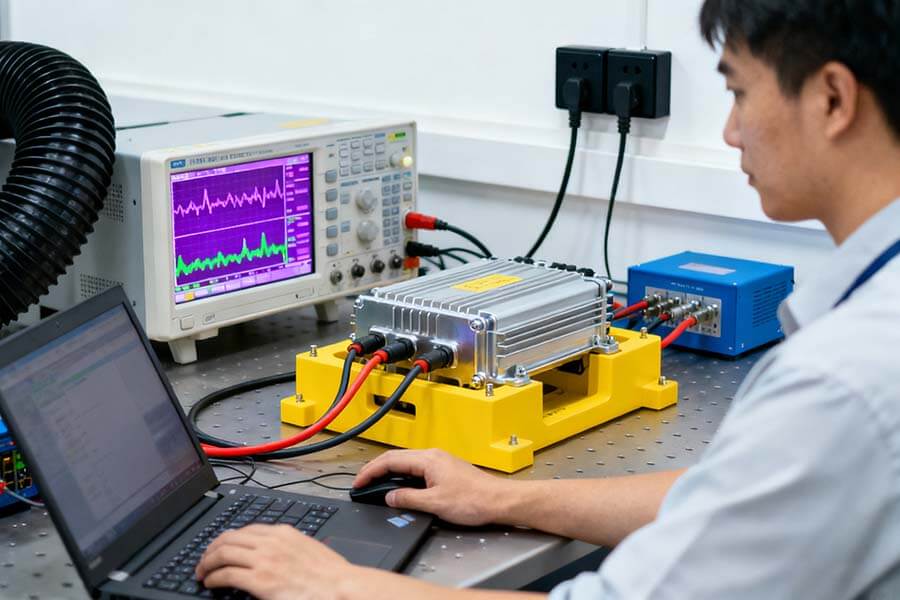

The Master Translator: The Inverter

Sitting between the battery and the motor is the inverter. Its job is to convert the battery's Direct Current (DC) into the Alternating Current (AC) that drives the motor. It’s a master of precision, controlling the motor's speed and torque. But to test it, you need to simulate both sides of its operation.

How it tests the inverter:

· Motoring Mode (Drive): The bidirectional supply acts as the battery, providing high-voltage DC power to the inverter, which then drives the motor. Engineers can test the inverter's efficiency, thermal performance, and control algorithms under various load conditions.

· Regeneration Mode (Braking): This is the critical test. When the EV brakes, the motor becomes a generator, sending AC power back to the inverter. The inverter then converts this AC back to DC to charge the battery. The bidirectional supply acts as the battery receiving this power, allowing engineers to validate the inverter's rectification efficiency and stability during this complex energy reversal.

Why Bidirectional is a Game-Changer

So, why is a dedicated bidirectional instrument so much better than the old two-box approach?

1. Seamlessness: It transitions between sourcing and sinking power seamlessly and within microseconds. This is crucial for capturing the real-world, transient behavior of components during events like sudden acceleration or regenerative braking.

2. Energy Efficiency (and Cost Savings): In a traditional setup, the electronic load dissipates power as heat—a massive waste of energy, especially when testing at high power levels. A bidirectional DC supply recovers up to 96% of this energy and recirculates it back to the grid or to its source. This dramatically reduces electricity costs and the need for massive cooling systems, making test labs greener and more economical to operate.

3. Space and Simplicity: One compact instrument replaces two large ones, simplifying the test setup, reducing cabling complexity, and freeing up valuable lab space.

Powering the Future, Today

The shift to electric mobility is more than just swapping a gas tank for a battery. It's a fundamental re-architecture of the automobile, centered on sophisticated power electronics. As we push towards higher voltages (800V and beyond), faster charging, and ubiquitous V2G capabilities, the demands on test equipment will only grow.

The bidirectional DC power supply has proven to be the indispensable engine driving this R&D. By providing a flexible, efficient, and powerful platform for validation, it empowers engineers to build safer, more reliable, and more capable electric vehicles that are transforming our roads.

It’s not just a tool in a lab; it’s the catalyst ensuring the EV revolution doesn’t just start—but keeps accelerating.

*Please fill in the required information carefully, and we will contact you within 4-8 hours.

TEL:+86 532 83995188

TEL:+86 532 83995188

PHONE:+86 177 5322 5039

PHONE:+86 177 5322 5039

E-MAIL:service@ainuoworld.com

E-MAIL:service@ainuoworld.com

ADDRESS:No. 134 Zhuzhou Rd, Laoshan District, Qingdao, China

ADDRESS:No. 134 Zhuzhou Rd, Laoshan District, Qingdao, China

Copyright©2025. Aino Instrument Co., Ltd All Rights Reserved.

Powered by:WDL